| تاريخ البداية | تاريخ النهاية | الدولة | المدينة |

|---|

+۹٦٦ ۹۲۰۰۰۷۷۷۱

+۹٦٦ ۹۲۰۰۰۷۷۷۱

الأهداف

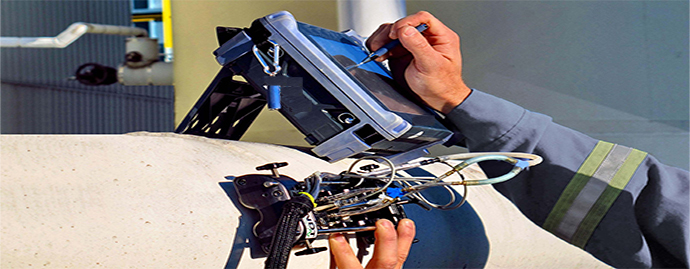

- The level II course considers the application of longitudinal, shear, surface and plate wave Ultrasonic Testing, comparing straight beam (Longitudinal Wave) and angle beam (Shear Wave) techniques. The application of shear wave testing for weld inspection is the major topic for this class, as well as consideration of heat-affected zone scans, surfaces and hydrogen embrittled cracking

- Also discussed are the advantages and limitations of Ultrasonic Testing as compared to Radiographic Testing of welds. The main focus is on the way shear wave examination parameters relate to each other and includes near field and beam spread, transducer design, incident, refraction and reflection angle variables amongst others. Level II Ultrasonic Testing certification procedures are also covered. And additional day is available to cover Nozzle Testing for those who require it.

الخطوط العريضة

- General Principles of Ultrasonic Wave Generation

- Principles of Shear Wave Generation

- Shear Wave system Calibration

- Ultrasonic Testing Variables

- Ultrasonic Testing Procedures

- Technique Development

- Indication Classification

- Industry Problems and Solutions Course also includes:

- Hands-On Training (Practical)

- Review & Discussions

- Daily Tests

- Examination

من ينبغى أن يحضر

- The course is designed for anyone who is interested in satisfying the classroom training requirements for Ultrasonic Testing Level II certifications or who needs a thorough knowledge and practical experience of Ultrasonic Testing methods and principles.

المدة

5 أيام