| Start Date | End Date | Country | City |

|---|

+966 920007771

+966 920007771

Objectives

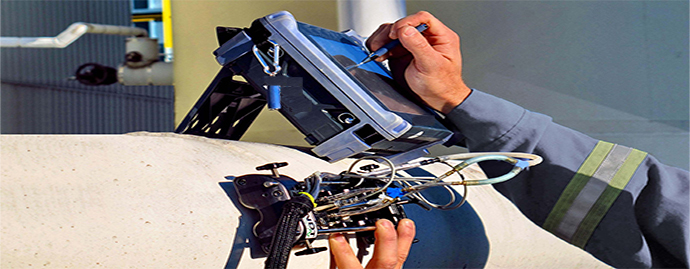

- The objective of the course is to present an overview of Eddy Testing, identifying the advantages and limitations of this as compared to other methods of Non-destructive Testing.

Outlines

- Definition of conductivity and permeability, factors effecting them.

- Principle of eddy current testing. Standard depth of penetration. Factor effecting Std. Depth of penetration. Phase angle and its use.

- Test coil: type and construction. Edge effect, End effect, Fill factor, and Lift off. How they can be controlled.

- Coil Impedance, Selection of frequencies for different application.

- Testing techniques.

- Impedance testing.

- Phase Analysis

- Vector Point Method

- Ellipse method

- Linear time base method

- Modulation of frequencies. Course also includes:

- Conductivity measurement, Ferrite measurement, Materials sorting based on chemical composition, working conditions, heat treatment conditions.

- Defect detection in tube, pipe bars, welds and plates.

- Defect detection heat exchangers tubes.

- Dimensions monitoring of on tube, bar and wire manufacturing.

- Coating thk. Measurement on conductive materials.

- Plating thk. Measurement on conductive materials

Who Should Attend

- The course is designed for anyone who is interested in satisfying the classroom training requirements for Eddy Current Testing Level II certifications or who needs a thorough knowledge and practical experience of Eddy Current Testing Techniques.

Duration

5 Days