| Start Date | End Date | Country | City |

|---|

+966 920007771

+966 920007771

Objectives

To provide the designers, welding engineers and ambitious welders, welding inspectors with the important know how they need to do a good job. The course fills many gaps of knowledge they like to make it over.

Outlines

- Principles of Magnets and Magnetic Fields

- Theory of magnetic fields

- Earth’s magnetic field

- Magnetic fields around magnetized materials

- Theory of magnetism

- Magnetic poles

- Law of magnetism

- Materials influenced by magnetic fields

- Ferromagnetic

- Paramagnetic

- Magnetic characteristics of nonferrous materials

- Terminology associated with magnetic particle testing

- Characteristics of Magnetic Fields

- Bar magnet

- Ring magnet

- Effect of Discontinuities of Materials

- Surface cracks

- Scratches

- Subsurface defects

- Magnetization by Means of Electric Current

- Circular field

- Field around a straight conductor

- Right-hand rule

- Field in parts through which current flows

- Long, solid, cylindrical, regular parts

- Irregularly shaped parts

- Tubular parts

- Parts containing machined holes, slots, etc.

- Methods of inducing current flow in parts

- Contact plates

- Prods

- Discontinuities commonly discovered by circular fields

- Longitudinal field

- Field produced by current flow in a coil

- Field direction in a current-carrying coil

- Field strength in a current-carrying coil

- Discontinuities commonly discovered by longitudinal fields

- Advantages of longitudinal magnetization

- Disadvantages of longitudinal magnetization

- Selecting the Proper Method of Magnetization

- Alloy, shape and condition of part

- Type of magnetizing current

- Direction of magnetic field

- Sequence of operations

- Value of flux density

- Inspection Materials

- Wet particles

- Dry particles

- Principles of Demagnetization

- Residual magnetism

- Reasons for requiring demagnetization

- Longitudinal and circular residual fields

- Basic principles of demagnetization

- Retentivity and coercive force

- Methods of demagnetization

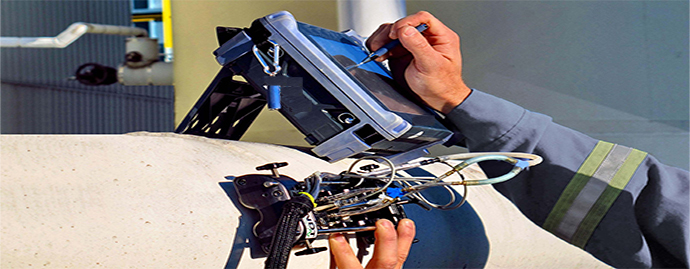

- Magnetic Particle Testing Equipment

- Equipment selection considerations

- Type of magnetizing current

- Location and nature of test

- Test materials used

- Purpose of test

- Area inspected

- Manual inspection equipment

- Medium- and heavy-duty equipment

- Stationary equipment

- Mechanized inspection equipment

- Semiautomatic inspection equipment

- Single-purpose semiautomatic equipment

- Multipurpose semiautomatic equipment

- Fully automatic equipment

- Types of Discontinuities Detected by Magnetic Particle Testing

- Inclusions

- Blowholes

- Porosity

- Flakes

- 5 Cracks

- Pipes

- Laminations

- Laps

- Forging bursts

- Voids

- Magnetic Particle Test Indications and Interpretations

- Indications of nonmetallic inclusions

- Indications of cracks

- Indications of surface seams

- Indications of laminations

- Indications of laps

- Indications of bursts and flakes

- Indications of porosity

- Nonrelevant indications

Who Should Attend

Engineers and highly qualified technicians working, in the design, manufacturing and testing of welded structures.

Duration

3 Days