| Start Date | End Date | Country | City |

|---|

+966 920007771

+966 920007771

Objectives

The trainee will be able to: -

- Safe practice for welding activities and inspection

- Understand the effective points in famous welding process

- How to select the correct welding electrodes for several applications?

- Main feature of some steel and steel alloys and its applications

- Destructive test to evaluate metal properties

- Read and understanding welding map and welding symbols

- Understand welding defects and how to control it

- How to reviewed welding procedures and welder qualifications

- Understand the main deference of codes, standard and specifications and priority of each other

- Monitoring NDT methods to inspect welding joints

Outlines

The trainee will be able to: -

- Safe practice for welding activities and inspection

- Understand the effective points in famous welding process

- How to select the correct welding electrodes for several applications?

- Main feature of some steel and steel alloys and its applications

- Destructive test to evaluate metal properties

- Read and understanding welding map and welding symbols

- Understand welding defects and how to control it

- How to reviewed welding procedures and welder qualifications

- Understand the main deference of codes, standard and specifications and priority of each other

- Monitoring NDT methods to inspect welding joints

Materials types

Ferrous

- Carbon Steel types

- Stainless steel types

- Cast iron types

Non ferrous

- Nickel ant its alloy

- Cupper and its alloy

- Material properties

Strengths

Ductility

Hardness

Toughness

DPTT

- Destructive test to determine the material properties

Tensile test

Hardness test

Impact test

- International codes governing material industries and acceptance criteria for each material type such as

- ASTM and API codes

- introduction to welding and its roles in industrial sectors

- safety requirements in welding activities

eye, ear, face and head protection

protection clothes

- welder’s levels (level I level II and level III) according to AWS rules

- introduction to the main welding process

- welding positions (1G ,2G ,3G, 4G,5G,6G,6GR) and how the test occurs

- AWS standard for welding terms and definitions

- shielded metal arc welding (SMAW) process

machine parts

SMAW electrodes and how to read the electrode designation according to AWS designation

Different electrodes type and how to select

Low hydrogen electrode types and Preheat requirements for it

Heat input and the factors affecting it

- Process current

- Voltage

- Travel speed

Heat source in SMAW process and arc fundamentals

Flux as a shielding source in SMAW and its functions

Advantages and limitation for SMAW

Arc blow effect and how to eliminate

- SMAW applications

- Gas metal arc welding (GMAW) process

machine parts

GMAW electrodes and how to read the electrode designation according to AWS designation

Different electrodes type and how to select

Modes of transfers

Different gas types and its advantages and limitation

- Argon

- Helium

- Co2

- Mixed gas

GMAW applications

Advantages and limitation for GMAW

- Flux cored arc welding (FCAW) process

machine parts

FCAW electrodes and how to read the electrode designation according to AWS designation

Different electrodes type and how to select

Different gas types and its advantages and limitation

- Argon

- Helium

- Co2

- Mixed gas

- Self-shielding without using gas

FCAW applications

Advantages and limitation for FCAW

- Gas tungsten arc welding (GTAW) process

machine parts

GTAW electrodes and how to read the electrode designation according to AWS designation

Different electrodes type and how to select

Different gas types and its advantages and limitation

- I1 gas type and its uses

- I2 gas type and its uses

- I3 gas type and its uses

GTAW as a common process in welding stainless steel materials

Injection gases in GTAW and its roles in welding quality

Advantages and limitation for GTAW

- Over view on EBW, ESW, OAW, LW and friction welding

- Submerged arc welding (SAW)

Machine parts

Welding electrodes

Different shielding flux

Uses in fit up sections

W/D ratio and its effect on welding variables

- welding joint geometry& welding symbols and NDE symbols

AWS A3.0 standard welding terms and definitions

AWS A2.4 welding symbols

Joint types

- Butt joint

- Lap joint

- Corner joint

- T – joint

- Edge joint

Applicable weld for each joint type

- Fillet weld

- V-groove weld

- J- groove weld

- Flare bevel grove

- Bevel groove

- Plug, spot, slot seam and braze

- Documents governing welding, inspection and qualifications

Documents types

- Drawing

- Codes

- Standard

- Specifications

- Recommended practices

- ITP

Qualifications

- Welders

- Takers

- WPS & PQR

AWS D1.1 and ASME IX for welder and welding joint qualifications

- P- numbers of different materials

- Essential and non-essential welding variables

- type of DT required for each case and No. of specimens

- Welding defects and hoe to avoid and repair it

Cracks

Under cut

Porosity

Lack of fusion and penetration

Slag inclusion

Cap reinforcement and excessive root

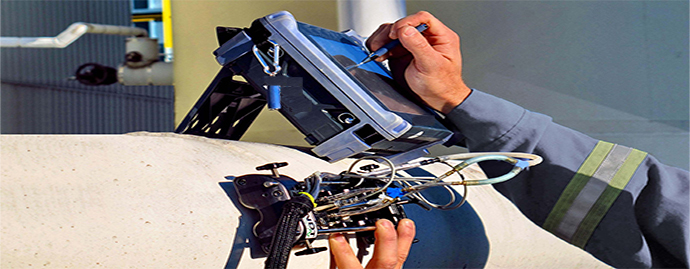

- Over view for NDT methods

VT tools and practical training on using it to measurement welding defects and repot form

PT and MT

RT and practical training for film interpretation

UT and practical training for using thickness measurements tools

Who Should Attend

- Welding technicians (welders, fitters, and helpers)

- Welding supervisors

- Material engineers

- Receiving material inspectors

- All site engineers (welding – fabrication- inspection)

- Design engineers

Duration

5 Days