| Start Date | End Date | Country | City |

|---|

+966 920007771

+966 920007771

Objectives

- ‘Welding Inspector’ certificate is a much sought after qualification in Petrochemical industry. To qualify for the examination, candidates must have some minimum work experience in the welding field. However experience without sound theoretical knowledge is has very low usefulness.

- This course covers all the theoretical fundamentals required of a welding inspector. The course will also include mockup examinations to help participants access their preparedness for AWS / CSWIP examination

Outlines

- Duties of Welding Inspector:

- Study relevant codes, specifications & drawings

- ‘Fit Up’ inspection

- Inspection during welding

- Finished Weld Inspection

- Reporting Welding Terminology:

- Types of joints

- Types of Welds

- Weld Sequence Welding Symbols:

- Definitions

- Weld Symbols

- Welding Symbols Metal structure and properties:

- Crystal Structures & Phases of Iron

- Strength

- Hardness

- Ductility

- Toughness

- Fatigue

- Endurance Limit Welding Metallurgy:

- Phases & Effect of Heat Treatment

- Annealing

- Quenching Welding Processes:

- SMAW

- GMAW

- GTAW

- SAW

- PAW

- Stud Welding

- EBW

- Electro slag welding Destructive Testing:

- Tensile Test

- Charpy / Izod Test

- Hardness Test Welding Discontinuities:

- In Parent Metal

- In Fit up

- Root discontinuities

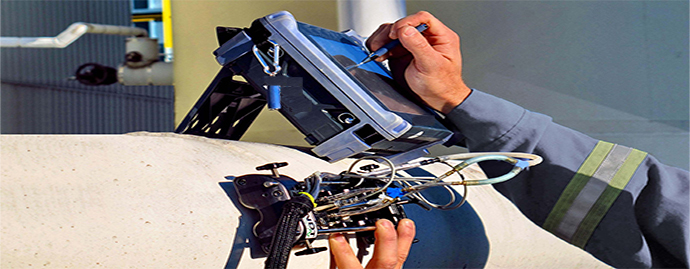

- Profile discontinuities Non Destructive Testing:

- Visual Testing

- Penetrant Testing

- Magnetic Particle Testing

- Ultrasonic Testing

- Radiographic Testing Codes and Standards:

- API 1104

- ASME Sec IX

Who Should Attend

- This course is intended for maintenance, inspection and production engineers, who seek to have basic understanding of Welding Inspection.

- This course thoroughly prepares students for AWS / CSWIP welding Inspector Examinations with guaranteed results.

Duration

5 Days